How to start a business producing processed meat products. Production of semi-finished meat products - opening our own workshop

Semi-finished products are food products made from meat or other minced meat with flavoring and stabilizing additives.

There are several types of semi-finished products:

- by methods of processing raw materials: natural, chopped, or processed, breaded products and dumplings;

- depending on the type of raw materials used: beef, pork, lamb, chicken, rabbit products and offal;

- according to storage method: chilled, frozen.

Semi-finished products contain various additives: water, flour and cereals, sugar, salt, spices, eggs and egg products and other ingredients. The quantity and quality of additives often affects the taste of the product.

Technology for the production of semi-finished meat products

And when purchasing equipment, you need to understand what stages the technological process consists of. First, frozen food in the form of large briquettes arrives at the plant, and is first defrosted and crushed. Defrosting, or defrosting, is very important: improper organization of the process leads to loss of taste and freshness of raw materials. Optimal conditions for defrosting are defrosting for 12-16 hours at a temperature of 20˚C and air humidity of 95%.

The cooled raw materials are ground in a meat grinder, then to obtain a homogeneous mass, the minced meat and additional ingredients (spice, water and others) are placed in a minced meat mixer. The device helps to make the mass homogeneous, saturate the minced meat with oxygen, which improves the taste and appearance of the prepared dishes.

After the mince mixer, the mixture enters the molding machine. The product is given a certain size and shape according to the recipe.

If the recipe requires semi-finished products to be breaded, then after giving shape they go into a sheeting machine and into a breading machine.

For dumplings, it is additionally prepared using a dough mixer. The minced meat and dough are placed in dumpling machines, and the finished product is sent along a conveyor for freezing. The final stage is freezing and packaging.

In industrial conditions, blast freezing is used, allowing you to freeze products in 20-30 minutes. To implement this stage, a blast freezing chamber or a compact spiral freezer is required.

Products are packaged in plastic bags or cardboard boxes manually or using special machines.

Equipment for the production of semi-finished meat products

A small enterprise does not require the purchase of expensive equipment; to begin rational use of funds, you need to correctly calculate the production capacity.

Main equipment for the production of semi-finished meat products:

- Band-saw needed for making bars from large pieces of raw materials that are easy to process. The cost of saws varies from 45 to 300 thousand rubles. For a small plant, models from Russian manufacturers RostPischMash and MM Pris are suitable.

- Meat grinder- a machine for turning meat into minced meat. The cost of the machine ranges from 40 to several hundred thousand rubles. When choosing a meat grinder, you need to focus on the planned production volume. In small factories, it is enough to use reliable machines from the Belarusian manufacturer Torgmash: MIM-80 meat grinders allow you to produce up to 80 kg of minced meat per hour.

- Minced meat mixer gives the minced meat a uniform consistency and airiness. The cost of the machine is 60-300 thousand rubles. For a small plant, it is enough to purchase a 50 liter unit from the RostPishchMash enterprise.

- Molding machine necessary to create products of a certain size and shape. Depending on the type of molding machine, several types of semi-finished products can be produced simultaneously, for example, meatballs and cutlets. The cost ranges from 25 to 450 thousand rubles. For small businesses, a machine from the Russian manufacturer RostPishchMash is ideal, allowing the production of 2000 units. products per hour.

- Tray sealer needed for packaging finished products. The cost of equipment is from 150 thousand to a million rubles. Semi-automatic machines from the Russian company CAS are suitable for a small enterprise.

assumes the presence of dumpling machines, a dough mixer and a flour sifter. Do not forget about the freezer, separate rooms for storing raw materials and finished products, sanitary products and consumables.

Requirements for a production workshop

According to sanitary standards, the workshop must meet the following parameters:

- Air temperature – 18-20˚С;

- Humidity – 40-60%;

- Water supply and sewerage must be centralized, the quality of drinking water must comply with GOST R 51232-98;

- Rated voltage in the electrical network is 380 V.

There are also regulatory documents (SNiP, SanPiN and others) for different premises of the enterprise and stages of production.

Staff

To begin with, it is enough to hire 2-3 workers per shift. In addition to workers, we need a chef, a logistics specialist, an accountant, a housekeeping manager, an IT specialist, a technologist, and a cleaner. As the plant develops, the number of personnel will increase.

Documentation

Collecting documents when organizing a business is the most important part. Before that, a legal entity is registered. You can become an individual entrepreneur (IP) or organize a limited liability company (LLC). This takes into account the size of the business and the difference in taxation systems.

Besides, before starting production, you need to obtain permission from the sanitary and epidemiological service and issue certificates of conformity for the entire range.

When collecting documents, a beginner should consult with a lawyer and equipment suppliers.

Conclusion

Before you start, you should consider the channels for selling products and the need for an advertising campaign. You need to be ready to confront competitors and constantly improve production. We should also not forget about government programs that help solve a large number of small business problems.

Total: 14 units, 2 suppliers, prices from 22,650 to 3,007,315 rubles.

Main aspects of organizing the work of a workshop for the production of semi-finished meat products. Particular attention is paid to the selection of equipment used to obtain a different range of this type of product and to the analysis of its characteristics. The presented diagram of the technological process of preparing semi-finished products allows us to better imagine the sequence of its stages.

Purpose

The subject of production is natural large and small pieces (entrecotes, steaks, cutlets, frying, azu, shish kebab), as well as chopped semi-finished meat products (meatballs, meatballs, cutlets, meatballs). Natural semi-finished products are sold chilled for sale in retail chains, while chopped products are sold frozen.

Raw materials

The main types of raw materials for the production of semi-finished meat products are:

- pork, beef, poultry;

- lard;

- breadcrumbs;

- salt, spices.

Required equipment

Most of the technological operations for the production of semi-finished meat products are mechanized and performed using specially designed equipment, which includes:

- band-saw;

- meat grinder;

- mince mixer;

- cutlet forming machine;

- slicer;

- meat ripper;

- packing machine;

- cooling chamber.

Each of the listed types of production equipment has unique functions, advantages and disadvantages that should be taken into account when technically equipping the enterprise.

Band saws for bones and meat

Band saws are machines used for cutting animal carcasses or frozen meat briquettes into portions of a certain size, which greatly simplifies and speeds up further processing of raw materials. Their use guarantees complete preservation of the weight of the product and ensures that the pieces are neatly cut, without splinters of bones.

The design features of the strip slabs allow you to adjust the height and thickness of the cut. All parts in contact with the product are made of stainless steel, and are easy to use and safe.

There are many models of band saws from different manufacturers on the market. The cost of the proposed equipment ranges from 45 to 270 thousand rubles. and largely depends on its productivity, which in most models is 300-500 kg/h. For small enterprises, taking into account their capacity, the optimal solution would be to choose saws from Russian companies MM PRIS, RostPishchMash.

More expensive models from SIRMAN (Italy) or Mainca (Spain) are an excellent option for large food production.

Meat grinders are designed for grinding meat

The machines are equipped with a set of replaceable knife grids with different hole diameters. By installing the appropriate set of them, the degree of grinding of raw materials is regulated: for example, minced meat for natural chopped semi-finished products should consist of larger pieces. Equipment of this type is available in floor-standing and table-top versions and has devices that ensure safe operation.

The minimum cost of industrial meat grinders is about 10 thousand rubles. Its upper limits are not limited - individual companies sell cars at a price of 400 thousand rubles. When choosing a model for a small enterprise, you should first of all be guided by the planned quantity of products. The best option is traditional MIM meat grinders, producing from 80 kg of minced meat per hour, produced by the Belarusian company Torgmash.

Powerful meat grinders model KT LM with a capacity of up to 1150 kg/h from Koneteollisuus (Finland) are suitable for large-scale production.

Meat mixers

To obtain a uniform consistency, all products included in the minced meat are mixed using minced meat mixers. During this process, the mass is saturated with oxygen from the air, becomes fluffy, and the products prepared from it after heat treatment become juicy and appetizing. The recommended duration of mixing one portion is 60 seconds; with a longer process, the fat begins to separate from the meat and stick to the inner walls of the machine, which deteriorates the quality of the finished products and makes them dry.

The cost of minced meat mixers is in the range of 50-300 thousand rubles. Like other equipment, it is directly related to the performance of the machine. For small businesses, the widest range of models with a working chamber volume of 50 liters or more is presented by RostPishchMash.

Foreign manufacturers, for example, the Italian companies La Minerva and SIRMAN, offer equipment that is more powerful and expensive, aimed at use in large food production facilities.

Cutlet forming machines

Cutlet forming machines are necessary for giving shape to products. Some models have a replaceable molding table with holes of different configurations, which makes it possible to alternately prepare several types of semi-finished products, for example, cutlets and meatballs. This type of equipment has high productivity and allows you to produce products of a given weight and size.

The cost of cutlet-forming machines depends on the number of attached replaceable dies and productivity and ranges from 24-450 thousand rubles. The most expensive and highly productive (up to 2500 pcs/h) - from Gaser - are intended for large-scale production.

Their Russian analogue, RostPishchMash, with a productivity of 2000 pieces/hour, is more affordable in price and ideal for small businesses.

Slicing machines

Slicing machines are used to produce natural portioned and small-sized semi-finished products. They are characterized by high productivity and provide products that have a neat shape and the same weight. Meat can be cut frozen, chilled or fresh, while the quality of its processing remains consistently high and the percentage of waste is minimal.

Portion cutting machines have a high cost: from 700 to 1500 thousand rubles. They are not produced by Russian manufacturers, but the most famous foreign one is the German company Treif Maschinenbau GmbH, which offers models of various capacities, from 180 to 400 cuts/min, among which you can choose a machine for both small and large enterprises.

Meat rippers

Meat rippers are used for loosening portioned pieces of meat intended for frying, as well as for “stitching” them. Using special knives, cuts are made on the surface of the product on both sides so that during cooking the piece of meat is not deformed and the finished dish is soft and juicy. At its core, the loosening operation is a mechanized analogue of beating. This type of equipment is equipped with safety systems to ensure safe operation.

Meat rippers presented on the equipment market have different productivity (from 1000 to 2500 pcs/hour) and cost (from 30 to 180 thousand rubles), which are directly dependent. For small businesses, machines produced by OMAS (Italy) are an excellent option, offering optimal price-quality ratio.

Prepared semi-finished products are packaged and packed in trays. For this purpose, automatic or semi-automatic tray sealers are used to ensure the tightness of the packaging, thereby significantly increasing the shelf life of the products.

Package

Tray sealers have different levels of productivity and automation and make it possible to simultaneously pack from 1 to 4 trays of semi-finished products. The cost of such equipment is in the range of 150-1000 thousand rubles. For small businesses, semi-automatic machines from the Russian company CAS, which are not inferior in their characteristics to foreign analogues, would be an excellent option.

Storage

To store semi-finished products before sale, refrigeration equipment is used - chambers or cabinets, preferably combined or low-temperature ones. For small businesses, it is advisable to purchase 2 chambers: for storing refrigerated and frozen products. These can be both chambers with a combined mode or, one each, with low temperature and medium temperature. Recommended internal volume – from 10 m3.

Technological cycle

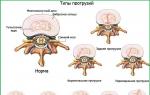

Technological cycle of production of semi-finished meat products

Technological cycle of production of semi-finished meat products

Premises and communications

A workshop for the production of semi-finished meat products must meet the following requirements:

Requirements for premises and communication systems of production workshops are set out in various types of regulatory documentation: SNiP, SanPiN, etc. Compliance with them guarantees the production of products that are safe for consumer health and minimizes the risk of contamination with pathogenic bacteria that can cause food poisoning.

Modern people do not always find time to prepare their own food, so semi-finished meat products are always in great demand among the population. According to experts, this trend is associated with an increase in the well-being of our country’s citizens and their income level. A workshop for the production of semi-finished meat products as a business will generate good income if you are able to competently set up production and choose a range of products.

What are semi-finished products?

These are portioned products made from minced meat or other raw materials with all kinds of additives.

Such products are divided into the following types:

- By processing method: natural and chopped.

- By type of meat: rabbit, poultry, pork, beef or lamb.

- Thermal condition: chilled and frozen.

Additionally, these products may be natural or processed.

Registration of activities

Before opening a workshop for the production of semi-finished products, it is necessary to obtain all permits and register your business with government agencies. This is the main problem that new entrepreneurs face.First of all, you need to register a legal entity. You can open an individual entrepreneur or LLC. Also, for the production of semi-finished products you need to obtain permission from the SES. In addition, you need to prepare a production control program and certify all types of products. Since the list of standards and requirements for the production of semi-finished products is quite large, it is advisable to involve specialists in this matter who will collect all the necessary documents.

Workshop room

In order to open the production of semi-finished meat products, you need to select a premises that will meet all the requirements of the fire inspection and Rospotrebnadzor. Otherwise, you may be denied permission to carry out this type of activity. The best option is a room in which a cooking room, dining room or kitchen was equipped. Such areas are much easier to tidy up.

For mini-production of semi-finished products, an area of 50–70 square meters is sufficient. meters. If you plan to expand your business in the future, you should foresee this in advance and rent a large room with good lighting, ventilation and fresh air. It must be supplied with hot and cold water, as well as sewerage and electricity.

The production workshop can be located directly in a populated area or on its outskirts. Pay attention to the access roads for the shipment of finished products and the receipt of raw materials for the production of semi-finished products. In addition, next to the workshop there should be a warehouse with refrigeration equipment for storing meat and finished semi-finished products.

Equipment

The most important point is the choice of equipment for the production of semi-finished meat products. You will need:

- Meat grinder;

- Mince mixer;

- Dough mixing machine;

- Apparatus for making dumplings;

- Molding machine;

- Cooling chamber;

- Breading machine;

- Lizoning equipment;

- Blast freezing cabinet;

- Refrigerated chest;

- Packaging machines;

- Scales.

Scheme: technology for preparing semi-finished meat products

When selecting equipment for the production of semi-finished meat products, pay attention to its reliability, ease of use, as well as maintainability and availability of spare parts. Before purchasing units, you need to decide what kind of semi-finished products you plan to produce. To reduce start-up costs, you can purchase used equipment.

Technological process

Let us consider in more detail the technology for the production of semi-finished meat products. If raw meat enters the workshop frozen, it is crushed using a special crusher. After this, add bacon, water, spices, salt, etc. to the minced meat. Then it is kneaded in a minced meat mixer until the mass becomes homogeneous.

To form finished products, a screw or rotary machine is used to form semi-finished products. At this stage, the product is weighed and given a certain shape. Finished products are transported via a conveyor belt to a sheeting machine, and then to breading equipment.

Another important stage is shock freezing of the product. After this, it can be packed in polyethylene or cardboard boxes. Before sale, finished products are stored in freezers. In order for the production of frozen semi-finished meat products to bring good profits, you need to strictly adhere to the technology of their production. Otherwise, your product will be unclaimed, resulting in the company going bankrupt.

Staff workers

In order to establish the production of semi-finished products as a business, it is necessary to hire qualified workers. At such an enterprise it is impossible to do without an experienced technologist, since the quality of the products directly depends on this. At first, you can hire 5–7 workers to work in the workshop. In addition, do not forget about the administrative staff - directors and accountants. At first, these responsibilities can be assumed by the owner of the enterprise.

For large production you will need:

- Carvers;

- Molders;

- Dough mixers;

- Controllers;

- Packers.

Despite the fact that almost all equipment for the production of semi-finished meat products is automated, each unit must be serviced by a worker. To establish round-the-clock production, you need to install 3 shifts of 8 hours at the enterprise.

To sell finished products, you need to hire a sales representative, driver and forwarder.

Expenses

When drawing up a business plan for the production of semi-finished meat products, it is necessary to take into account the following costs:

- Rental of production space – 550 thousand rubles;

- Repair and decoration of the premises - 210 thousand rubles;

- Purchase of equipment – 680 thousand rubles;

- Salary to employees – 2.8 million rubles per year;

- Working clothes and tools – 80 thousand rubles;

- Raw materials – 600 thousand rubles;

- Additional expenses 160 thousand rubles.

In general, it will take about 5 million rubles to open a business. If you produce high-quality products, such an enterprise will pay off in the first year of operation by the end of the third quarter.

Sales markets

When developing a business plan for the production of semi-finished products, it is necessary to pay special attention to the marketing of finished products. Despite the fact that such a product is in great demand in branded and regular food stalls, do not think that you will not have any problems selling it.

These are quite specific products that require special storage and transportation conditions. Therefore, it is better to cooperate with distribution companies that supply goods to large stores and supermarkets, as well as with wholesale centers selling semi-finished products. In this case, you will have to give the goods for sale or make a 10–15% discount.

If you want to set up home production of semi-finished products, you can sell finished products to small shops in rural areas. Their owners go to purchase on their own, so they will be happy to receive high-quality inexpensive goods with delivery. When looking for clients, take the finished product with you so that potential buyers can see and taste it.

So, you have decided to open the production of semi-finished products as a business, what is needed for it to be successful and generate good income?

A positive aspect and an undeniable advantage of the business for the production of semi-finished products is the ability to change the assortment, depending on the needs of the market. There are many types of meat dishes, and even during a shift you can produce cutlets and meatballs. Moreover, the equipment for the production of pancakes or semi-finished meat products does not even need to be reconfigured.

Frozen food is a product that is subject to certification. To obtain permission to sell products to a retail chain, you need to register the workshop as an enterprise. When choosing a form of ownership, you need to take into account that large retail chains prefer to work with LLCs. Permits for activities must also be obtained from the sanitary and epidemiological station. A declaration of conformity is issued for the products.

Production technology

The taste of semi-finished meat products is influenced by the quality of raw materials. It must be fresh, and a veterinary certificate usually accompanies each batch of goods. When entering the meat products workshop, raw materials are additionally controlled.

The technology consists of several operations:

- preparation of raw materials;

- cooking minced meat;

- product formation;

- packaging, warehousing and sales.

If meat is purchased in carcasses, then you need to cut it. This process is called boning. All bones and veins must be separated from the raw material. Next it is ground into minced meat. If the product is prepared from a pork-beef mixture, then the raw materials are taken in a 50/50 ratio. Spices and other ingredients are added to the already crushed basic raw materials. It could be onions, bread, water, salt. The temperature of the mixture ready for shaping should not exceed 14 degrees, otherwise not only the taste of the product will be affected, but also its bacterial characteristics. Often in modern production, natural raw materials are partially replaced with vegetable ones. Soy is added to the minced meat, eggs are replaced with egg powder, etc. You need to be careful with them as they affect the taste of the final product.

Products are formed on a molding machine. Then the semi-finished meat products are subjected to shock freezing.

What equipment is needed?

The workshop for the production of frozen semi-finished meat products is equipped with the following equipment:

| Band saws for meat and bones | These installations help to cut meat and cut it without the formation of bone fragments. The first stage of raw material preparation, thanks to their use, occurs quickly and efficiently. Band saws are designed in such a way that they allow you to adjust the thickness and height of the cut. All surfaces that directly touch the products are made of stainless steel. The productivity of such installations is on average 300-500 kg/h. The price of the equipment depends on this indicator. It starts from 45 thousand rubles and can reach 270 thousand rubles. You can buy domestically produced machines for the workshop; imported units are usually more expensive. |

| Meat grinder | Industrial meat grinders for the semi-finished meat products department are equipped with a set of grates with different diameters. Thanks to this, it is possible to obtain minced meat of different consistencies for different semi-finished products. Meat grinders can be placed on the floor or on the table, depending on the design. Professional meat grinders with sufficient power for production cost from 10 thousand rubles. The upper threshold is not limited. There are models that cost 400 thousand rubles. Optimal for production, and therefore most often used, are the Belarusian-made MIM models. Their productivity is 80 kg/hour. This is quite enough to serve a small meat products shop. For very large enterprises there is equipment with a capacity of 1150 kg/h. It is mainly made in Europe. |

| Minced meat mixer | An installation that ensures uniform mixing of all minced meat ingredients. In addition, it is saturated with oxygen and its taste improves. The cost of minced meat mixers for a semi-finished meat product shop also directly depends on productivity. The price range is from 50 to 300 thousand rubles. When choosing, you need to pay attention to the volume of the working bowl. For small and medium-sized production, a 50-liter tank will be sufficient. Such units are produced by domestic enterprises. |

| Cutlet forming machine | This device is needed to give products a certain shape and size. The weight of cutlets or meatballs will also always be the same. The machine is equipped with holes (matrices) of different configurations. They allow us to produce a wide range of products. The price of this equipment depends on the number of products produced and ranges from 24 thousand rubles to 450 thousand rubles. The productivity of such devices is, on average, 2-2.5 thousand units/hour. This is enough to equip a medium-sized meat products workshop. |

| Meat slicing machine | It helps to cut semi-finished products into equal slices. The meat can be cut fresh or frozen. This does not affect the quality. Such machines are characterized by high productivity (180-400 cuts per minute). They cost from 700 to 1500 thousand rubles. There is no equipment from domestic manufacturers on the market, so it must be purchased only from an imported manufacturer. |

| Equipment for packing | Usually, tray sealers are purchased for packaging semi-finished products. They can simultaneously complete from 1 to 4 packages. The cost of such a machine ranges from 150 to 1000 thousand rubles. Small and medium-sized enterprises successfully use domestic CAS equipment in production. |

| Refrigerators and freezers | Low temperature refrigerators and freezers are used. Different chambers are used to store frozen and chilled products. To equip a small workshop for semi-finished meat products, you will need two of them. The internal volume of each must be at least 10 cubic meters. m. |

Most people find less and less time to cook their own food. In the modern world of constant rush and development of new technologies, it would be wrong not to take advantage of this fact. Therefore, a workshop for the production of semi-finished meat products seems a very tempting idea. Of course, it is much easier to start such a business with a ready-made business plan, examples of which you can find, and, if desired, buy at. Let's try to figure out how profitable and justified it can be.

Types of semi-finished products

The name “semi-finished product” itself implies a product that is already half ready; the consumer can only carry out the final stage of the technological process - preparation.

According to experts, this market segment is expected to grow increasingly in the coming years. Products of this kind can be classified according to several criteria:

- by processing method: chopped and natural;

- by type of meat used in the cooking process: pork, beef, chicken, rabbit, lamb, mixed;

- by thermal state: frozen, chilled.

In addition, all products can be divided into natural and processed:

- natural – chopped, large-piece, meat-and-bone, portioned, small-piece, pickled and other sets;

- processed - cutlets, meatballs, meatballs and other products made from processed minced meat.

A separate group includes dumplings, khinkali, and pancakes.

Permits

If the question of how to open a workshop for the production of semi-finished products has seriously interested you, then it should be recalled that this type of activity involves contact with food, and therefore you should start by obtaining all the necessary permits to open such an enterprise. Our business plan, which you can view and purchase, will help you not forget anything and adhere to the right actions.

The first step is business registration. The best form in this case would be an LLC, since, as practice shows, it is much easier to sell products as a legal entity. After this, you need to register with the tax authority and obtain a taxpayer certificate.

Certification

The next stage is product certification. Here you will need:

- permission from the SES;

- your production control program;

- permission from Rospotrebnadzor;

- certificates for all types of products.

All workshop employees must have health certificates. You also need to attach to the package of documents permission from the fire department to carry out this type of work in a specific premises and a lease agreement for the building.

Selecting a location for production

Let’s immediately rule out the options for premises in which it is simply impossible to locate such production:

As for the space occupied, in order to open a workshop for the production of semi-finished products, which will provide a ton of products per shift, you will need 20 square meters. In addition to the workshop itself, the building must have rooms intended for personnel, showers and toilets, as well as a warehouse for storing finished products and raw materials.

A good location option would be an area close to farms that breed animals. They can become your suppliers, and you can save on transportation costs.

Staff

It is necessary to select personnel to maintain the workshop. You should immediately take into account that at least three people will be needed to work with the installation on one shift. In addition, you should hire the following specialists:

At the first stage, when your company is just opening, you may not need some employees from this list yet, since one person will be able to combine several functions. But ideally, the staff should look like this.

Equipment

The biggest expense for starting a manufacturing plant is always the purchase of the necessary equipment. For this direction, this stage is the most important, since the speed and volume of production will depend on the quality and quantity of tools and machines.

So, equipment for the production of semi-finished meat products should include:

If your plans also include the production of dumplings, then you will additionally need a flour sifter, a dumpling machine, and a dough mixer.

Manufacturing process

Even if you are going to prepare semi-finished meat products according to your own recipes, the production process itself looks approximately the same.

To prepare minced meat products, the shoulder, neck, and thigh muscles, which contain more rigid connective tissue, are most often used. To begin with, the meat is ground, then eggs, spices, and fat are added to it. The minced meat is then passed through a grinder. Next, pork lard, water, and salt are added to it. Then all this mass is kneaded in a minced meat mixer and loaded into a hopper to form cutlets, meatballs and other products.

It is in this installation that the product acquires the specified shape and specified weight. From there, the cutlets go onto a conveyor, which delivers them for breading. Then the cutlets are placed in carts and sent to a blast freezing chamber; this process takes approximately 2 hours. Finally, the finished products are sent for packaging and storage in low-temperature refrigeration chambers.

Counting expenses

To get an overall picture, you can’t do without a preliminary calculation of expenses.

So, at the initial stage you will need:

Don’t forget about employee salaries and utility bills that you will have to deal with after just a month of work.

On average, we can say that to open a workshop you will need at least 5 million rubles. If the quality of the products meets consumer expectations, and you are able to provide sales markets, then the payback period will take about a year.

High quality business plan

This article widely covers the idea of starting the production of semi-finished products on your own, but in any case, when you start, you will need a high-quality business plan, which you can familiarize yourself with and purchase

Production of semi-finished products: Video