Potato starch production line

Starch is a fairly popular product in our area. It has found its wide application both in the food industry and in other areas. Many products are made from starch food products, as well as glue, paints, polymers and other products. It is important to stand out among the high competition of this business. It is most profitable to purchase a modern production line that will allow you to create four grades of raw materials: extra, highest, first, second. This way, you will be able to present customers with a wide range of products and allow you to purchase certain types of product for various purposes.

Starch can be created on the basis of many products - potatoes, wheat, corn. But it is potato starch that is most popular. Properties that many products allow you to create. Thus, it is better to start starting a business specifically from potatoes, and then, when production and sales of products are established, it will be possible to begin producing starch from other raw materials.

|

|

Renting premises.

It is not worth renting large production areas for starch production. 70-80 m2 is quite enough for the competent organization of both warehouse and production premises. When choosing a room, it is important to focus on a number of important points. First of all, these are increased requirements for fire safety. Small particles of starch can easily ignite if they come into contact with an open flame. Therefore, it is important that all fire safety techniques are taken into account. This issue is especially important at the production stage of drying products. Also, this production requires the organization and equipment of its own water treatment wastewater.

The location of such a production facility should be chosen outside the city. Best option- this is the area rural areas with the ability to receive potatoes almost immediately from the fields after harvesting. Further storage of potatoes will be carried out in warehouses. To store potatoes, the room must be clean, with a low level of air humidity and must be disinfected to prevent the appearance of pests. The cost of this type of premises will be about $600.

Equipment for starch production.

A modern starch production line allows you to create a product of four grades, which can automatically attract the attention of potential consumers. This line allows you to minimize the need for manual labor and allows you to obtain high-quality raw materials at the output. The main components of the production line are:

1. Special washing (it not only cleans potatoes, but also plays the role of a stone trap) - $8 thousand;

2. Industrial grater - $8 thousand;

3. Collection and storage for gruel - $20 thousand;

4. Centrifuge - $19 thousand;

5. Vacuum drying - $23 thousand;

6. Packaging equipment - $11.5 thousand.

The cost of such equipment is almost $90 thousand.

But by choosing such equipment, you can significantly reduce the cost of remuneration of workers and reduce the number of employees.

Staff.

To operate a medium-sized enterprise, a staff of at least 12 people will be required. These will be line operators, storekeepers, loaders, a driver, a security guard, an accountant, and a production line adjuster. The organization of labor for these workers will be handled by both the production manager and the business owner, if the appropriate skills are available. It is best to work in two shifts. When choosing personnel, it is necessary to focus both on work experience and education, and on the skills acquired during the production process. average salary workers will be about $250. In total, at least $3 thousand must be allocated for labor costs.

Raw materials.

The raw material will be potatoes that are of high quality and not damaged by pests. You can use both large and small tubers of certain potato varieties with a high starch content in the raw material. It is important to use only fresh and well-ripened product, then you will get the maximum percentage of starch from each unit of raw material.

Additionally, it is necessary to purchase such a component for the production of starch, sodium sulfate. To produce one ton of extra-grade starch, you need to invest at least $4 thousand in the purchase of high-quality raw materials.

Starch production requires developed advertising activities due to increased environmental competition. Creating your own website will attract buyers in the industrial sector and small and medium-level trading organizations. Execution of outdoor advertising in the production area will necessarily cover this consumer area.

Print publications will allow consumers to learn more about your product and will definitely grab their attention. But in order to catch a major client, you need to go to the intercity, interregional, and interstate level. By presenting your product at exhibitions and seminars, you can attract the attention of large and regular consumers, as well as learn more about your competitors. You must invest at least $500 in advertising.

Basic expenses.

The main cells for creating a manufacturing business are:

1. Rental of premises - $600;

2. Equipment - $90 thousand;

3. Staff - $3 thousand;

In total, to open your own starch manufacturing business you need to have a sum of $98 thousand.

Calculation of profit and payback period of investments.

A kilogram of potato starch costs about $1.2 on the market. This is the wholesale cost. A starch productivity of 1-1.5 tons per hour will entail about $55 thousand per month. After deducting all monthly expenses - purchase of raw materials, wages of workers, payment of rent, utilities, the net profit will be about $30 thousand. Provided 100% sales of products, you can completely recoup the business in 5-6 months. But, in practice, you should count on a period of at least 12 months.

Key consumers and direction development.

The main consumers will be small, medium and large trading organizations, industrial enterprises: food and non-food. When choosing an industry for business development, you can act in the direction of creating starch from another type of raw material. In the future, it is worth thinking about the production of modified starch, but this will require a series of laboratory studies.

|

|

Experts have long attributed the production of starch to a promising, profitable niche, which Lately has become popular among those entrepreneurs looking for profitable business ideas. If you buy equipment for starch production and arrange supplies of sufficient raw materials, you can as soon as possible recoup all investments made.

To start earning money, it is not at all necessary to launch a large-scale enterprise with huge capacities. The best option would be a mini workshop - this way you can minimize risks by investing less.

The production of starch will be beneficial to the entrepreneur for 2 main reasons:

- In Russia there are not very many manufacturers in this industry, which, of course, creates low competition here.

- Vegetable starch is in sufficient demand. And the bulk of buyers are wholesalers who buy starch as a raw material.

Our business assessment:

Starting investments – from RUB 3,000,000.

Market saturation is low.

The difficulty of starting a business is 7/10.

But we cannot fail to mention one significant drawback in this area. A mini starch production plant will operate in full force only in a certain season - from September to May. The fact is that in potatoes, after 250-300 days after harvest, the starch content begins to sharply decrease, which means that the raw material should be processed during this period. However, even this does not mean that the equipment will be idle during the off-season and all employees will have to be sent on vacation - the entrepreneur has the opportunity to establish starch and molasses production, when starch serves not only as a finished product, but also as a raw material for the further production of molasses. Molasses is an industrially valuable product obtained by hydrolysis of starch. It is an almost colorless viscous liquid with a sweetish taste.

It is very profitable to launch small starch production shops for private farms. Many enterprising businessmen do just this - they install a line near a potato or corn field to produce a high-quality product, which will then be sold on the local and regional market as additional profit.

What must be taken into account by an entrepreneur who decides to start the production of starch and molasses?

What raw materials can be used?

On many manufacturing enterprises starch is obtained from. And this is economically justified, since root vegetables today are widely available and inexpensive. Moreover, here it is possible to process not only large whole potatoes, but also small, not very good quality which are not suitable for sale. But producing starch from potatoes is not the only possible option.

To obtain a high-quality finished product, the following crops can be used:

- corn,

- wheat.

It’s great if you manage to arrange supplies of various types of raw materials - this way you can attract a more interested audience to your product.

Having established an uninterrupted supply of raw materials to production, the starch production line will not be idle. It is better to enter into agreements with local farmers, since potatoes, corn and wheat can be purchased from them at a reduced price.

As an additional raw material in production, containers will be used, which can be plastic or paper bags of different sizes. Metal or plastic barrels may be required for packaging molasses.

What assortment to offer customers?

The sale of starch will be much more active if we offer customers a full range of products. Now it is clear that the main classification of the finished product is carried out based on the raw materials from which it is made. Therefore, we try to orient our workshop to produce several types of starch at once, packaged in containers of different weights.

In addition, food starch can be divided into varieties. And the higher the grade, the higher the quality of both the raw materials and the output products.

There are four varieties in total:

- extra,

- higher,

- first,

- second.

When the company enters regional markets sales, it is possible to plan the production of modified starches. But this work is quite labor-intensive, not even in terms of equipment, but in terms of scientific development and obtaining quality certificates from regulatory authorities.

Technology for producing starch and molasses

The production of starch from corn, in terms of technology, differs little from the production of the same product, but from potatoes. Therefore, no matter what raw materials are supplied to the walls of the workshop, the operating principle of the equipment will remain unchanged.

The starch production technology is as follows:

- Preparation of raw materials (washing, weighing).

- Grinding raw materials to a pulp.

- Separating the pulp from the released juice.

- Obtaining free starch.

- Refining.

- Washing and drying the finished product.

In fact, the technological scheme for obtaining a dry product is complete. But if the plant also plans to produce molasses, then the potato starch is sent further for processing.

You can get molasses like this:

- Hydrolysis of starch in the presence of certain chemicals.

- Filtration of the solution.

- Discoloration of syrup.

- Evaporate the syrup to obtain molasses of a certain consistency.

- Pouring molasses into containers.

Both the production of potato starch and the production of molasses from it are relatively simple tasks even for a non-specialist in this field. But without having specific knowledge, it is better to invite a qualified technologist for consultations, who will work out the technology taking into account specific raw materials and select the equipment with optimal power.

Purchase of equipment for starch production

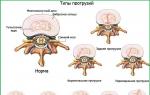

Starch production line

The production of starch from wheat and other raw materials will not be possible without special equipment. Regardless of what types of starch are planned to be produced at the output, the line includes the following machines and devices:

- Stone traps-washes.

- Industrial graters.

- Collection-storage of mush.

- Centrifuge.

- Vacuum dryer.

The price of equipment for starch production is quite high - at least 2,500,000 rubles. High-power complexes are even more expensive - up to 7,000,000 rubles. In expenses for technical equipment you need to include the cost of a special autoclave if the resulting corn starch is further used to make molasses. A good quality autoclave costs at least 400,000 rubles.

Profitability of the planned business

The production of wheat starch and its other types, as practice shows, despite the impressive investments (about 3,500,000 rubles), pays off quite quickly - within 2-3 years. But this is subject to full shipment of all manufactured products.

The production of corn starch will bring greater profits if you also sell molasses, because the cost of obtaining it is minimal. Wheat starch, corn and potato starch cost 35-50 rubles/kg on the wholesale market today. At the same time, its cost is 20-30 rubles/kg. As for molasses, it can be sold for 30-40 rubles/kg.

Due to the diversity of its properties and the ability to change them, starch is used in various food industries (confectionery, bakery, sausage, etc.), in cooking, for the production of starch products, in non-food industries (perfume, textiles, etc.).

Calorie content of 100g of starch is 350 kcal. In plant cells, starch is found in the form of dense structures called starch grains. Starch grains of different plants are characterized by a certain shape, structure, and size. Based on these characteristics, the type of starch can be determined. Starch can be made using various plant materials. However, the production technology is slightly different. In this article we will describe the technology for producing starch from potatoes and corn.

Potato starch production

The potatoes are washed to remove dirt and foreign inclusions in a potato washer, then served for chopping. The more it is crushed, the more complete the release of starch from the cells will be, but it is important not to damage the starch grains themselves. First, the potatoes are crushed twice on high-speed potato graters. The principle of their operation is to abrade the tubers between the working surfaces formed by saws with fine teeth mounted on a rotating drum. On the first grinding graters, the files protrude above the surface of the drum by 1.5...1.7 mm, on the second grinding graters - no more than 1 mm. During the second grinding, an additional 3...5% of starch is extracted. The quality of chopping also depends on the condition of the potatoes (fresh potatoes shred better than frozen or limp ones).

After crushing the tubers, ensuring the opening of most of the cells, a mixture is obtained consisting of starch, almost completely destroyed cell membranes, a certain amount of undestroyed cells and potato juice. This mixture is called potato porridge. Starch remaining in unbroken cells is lost as a by-product of production - potato pulp. This starch is usually called bound, and that isolated from potato tubers is called free. The degree of potato grinding is assessed reduction ratio

, which characterizes the completeness of cell destruction and the amount of starch extraction. It is determined by the ratio of free starch in the porridge to the total starch content in potatoes. During normal operation it should not be less than 90%. To improve the quality of starch, its whiteness and prevent the development of microorganisms, sulfur dioxide or sulfurous acid is added to potato porridge. The nitrogenous substances in juice include tyrosine, which is oxidized under the action of the enzyme tyrosinase to form colored compounds that can be sorbed by starch grains and reduce the whiteness of the finished product. Therefore, the juice is separated from the porridge immediately after grinding. Hydrocyclones are used to separate sand from the starch suspension and separate the pulp from potato juice. The principle of their operation is based on the centrifugal force generated during rotation. As a result of processing, a starch suspension with a concentration of 37...40% is obtained. They call her

To dry starch, continuously operating pneumatic dryers of various designs are most often used. Their work is based on the principle of drying loosened starch in a moving stream of hot air. The yield of finished starch depends on its content in the processed potatoes and on the loss of starch with by-products and wastewater. In this regard, the starch content in potatoes supplied for processing is standardized by the standard and should be at least 13...15%, depending on the cultivation zone.

When producing starch, it is produced in two forms: dry and raw potato starch. The amount of raw potato starch is determined in accordance with OST 10-103-88. There are raw starch grade A and grade B with a moisture content of 38 and 50%, respectively. Depending on the quality (color, presence of inclusions, foreign odor), raw starch is divided into three grades - first, second and third. Raw starch is a perishable product and cannot be stored for long periods; 0.05% concentration of sulfur dioxide can be used for preservation.

Dry starch is packaged in bags and small packages. Potato starch is packaged in double fabric or paper bags, as well as bags with polyethylene liners weighing no more than 50 kg. In terms of quality, starch, in accordance with the requirements of GOST 7699-78 “Potato starch” is divided into the following grades: “Extra”, highest, first and second. Starch moisture content should be 17...20%, ash content 0.3...1.0%, acidity 6...20° depending on the variety. The content of sulfur dioxide is not more than 0.005%. An important indicator characterizing the purity and whiteness of starch is the number of specks per 1 square dm when viewed with the naked eye. For “Extra” - 80, for the highest - 280, for the first - 700, for the second it is not standardized. Second grade starch is intended only for technical purposes and industrial processing. The guaranteed shelf life of starch is 2 years from the date of production at a relative air humidity of no more than 75%.

Corn starch production

IN general outline, the corn processing process can be described as follows: the shelled corn is softened in hot water containing sulfur. With coarse grinding, the germ is separated, and with fine grinding, fiber and starch are separated. The mill effluent is cleared of gluten and washed repeatedly in hydrocyclones to remove the last traces of protein and obtain high-quality starch.

CLEANING.The raw material for wet grinding is threshed corn. The grain is inspected and cobs, straw, dust and foreign materials are removed. Typically cleaning is done twice before grinding. After the second cleaning, the corn is divided into portions by weight and placed in bins. From the bunkers it is hydraulically fed into the locking vats.

SOAK.Proper soaking is a necessary condition high yield and good quality starch. Soaking is carried out in a continuous counter-current process. The shelled corn is loaded into a battery of large locking containers (tanks), where it swells in hot water for about fifty hours. In fact, steeping is a controlled fermentation, and adding 1000-2000 ppm of sulfur dioxide to the steeping water helps control this fermentation. Soaking in the presence of sulfur dioxide directs fermentation by accelerating the growth of beneficial microorganisms, preferably lactobacilli, while inhibiting harmful bacteria, molds, fungi and yeasts. The soluble substances are extracted and the grains are softened. The grains more than double in volume and their moisture content increases from approximately 15% to 45%.

Scheme of grain soaking at a plant with a capacity of 150 tons of corn per day

EVAPORATION OF SOAP WATER. The steep water is drained from the grain and condensed in a multi-stage evaporation plant. Majority organic acids, formed during fermentation, are volatile and evaporate along with water. Consequently, condensate from the first stage of the evaporation plant must be neutralized after heat recovery by heating the water supplied for soaking. The depleted steep water, containing 6-7% solids, is continuously withdrawn for subsequent concentration. The steep water is condensed into a self-sterile product - a nutrient for the microbiological industry, or concentrated to approximately 48% solids and mixed and dried with fiber.

SO2 PRODUCTION.Sulfurous acid is used to soak and soften the corn grain and control microbiological activity during the process. Sulfur dioxide is produced by burning sulfur and absorbing the resulting gas with water. Absorption occurs in absorption columns where the gas is sprayed with water. Sulfurous acid is collected in intermediate containers. Sulfur dioxide can also be stored in pressurized steel cylinders.

SEPARATION OF THE EMBER . The softened grains are destroyed in abrasive mills to remove the shell and destroy the bonds between the germ and the endosperm. Water is added to support the wet grinding process. Good soaking ensures free separation of the intact germ from the grains during the soft grinding process without releasing oil. Oil constitutes half the weight of the embryo at this stage, and the embryo is easily separated by centrifugal force. Light embryos are separated from the main suspension using hydrocyclones designed to separate the primary embryo. For complete separation, the product stream with the remaining germ is subjected to re-grinding, followed by separation on hydrocyclones, which effectively removes the residual - secondary - germ. The germs are washed repeatedly in countercurrent on a three-stage sieve to remove starch. Pure water added at the last step.

Separating the germ at a plant with a capacity of 150 tons of corn per day

Throughout last season, when there were not just a lot of potatoes in Russia, but a lot, the media repeatedly flashed reports that farmers were largely to blame for the losses they suffered: they knew that there would be more production than usual, but not prepared. At a minimum, they could purchase equipment and use these potatoes for starch. Indeed, in 2015, the country purchased almost 18 thousand tons of native potato starch (according to the Association of Russian manufacturers of starch products "Roskrakhmalpatoka"), while in Russia the production of this product decreased. And this downward trend has remained steady for several years.

A little history

Starch (and the history of the industry began precisely with potato starch) began to be produced on an industrial scale in Russia more than a hundred years ago. To obtain it, entire villages grated potatoes. The average artel produced about 25 tons of starch per year. There were more than a thousand such industries at the beginning of the 20th century. Most of goods were purchased by the textile factories of Morozov and Mamontov.

Large factories for the production of starch appeared by the 30s of the last century. And until the 90s, the industry was actively developing, meeting the needs of the food, pulp and paper, textile, pharmaceutical, chemical and oil and gas industries.

The years of perestroika became a difficult test for potato starch producers: in 1993, subsidies for the purchase of raw materials were canceled (purchase price of potatoes in Soviet years was 10 kopecks per kg, of which 4 kopecks were paid by the state); Borders have opened wide to foreign competitors.

As a result, out of 50 Soviet potato starch factories, no more than 10 remained, and even fewer were permanently operating - about five. The annual production of potato starch in Russia compared to 1990 has decreased from 50 to 5-8 thousand tons.

Since 1995, most enterprises have changed their form of ownership from state to private. The influx of investment allowed some of them to reconstruct and begin to overcome the crisis, but even today the situation with the production of potato starch in the country remains very difficult.

Oleg Radin, President of the Association of Russian Manufacturers of Starch Products "Roskrahmalpatoka"

- The situation with the production of potato starch in Russia can hardly be called rosy. Last year, the country processed about 30 thousand tons of potatoes, but according to the Research Institute of Starch Products, the dynamics are now falling. The main reason is the largest domestic producer of potato starch (previously supplying up to 500 tons of products per day) - Klimovsky Starch - on this moment is going through bankruptcy proceedings.

If in the countries of the European Union in the structure of raw materials the volumes of processing of corn, wheat and potatoes are approximately equal (30-35%), then in Russia the share of potato processing in the total volume of processed raw materials is only 5.0-6.5%.

Dmitry Lukin, director of the All-Russian Research Institute of Starch Products (FGBNU VNIIK)

- Production facilities for the production of potato starch operate only in Bryansk, Nizhny Novgorod, Oryol, Lipetsk regions, the republics of Mordovia and Chuvashia. The main producers of potato starch are: LLC Enterprise "Chuvashenstarch" (Republic of Chuvashia); LLC "Mglinsky starch" (Bryansk region), LLC "Syryatinsky starch" (Nizhny Novgorod region).

What is hindering the development of the industry today? Why are our factories losing the market to foreign manufacturers?

PROBLEMS OF THE INDUSTRY. Raw materials.

First of all, experts talk about the lack of a profitable raw material base in the country: the potatoes supplied for processing are of poor quality, not always in the required volume (as a rule, supplies go from September to March, April, then the starch content in potatoes decreases, which reduces the efficiency of its processing) and at a fairly high price.

Dmitry Lukin

- I would like to draw special attention to the low quality of processed potatoes, mainly in terms of starch content. The effectiveness of the technology for processing potatoes into starch is ensured by using tubers with a starch content of at least 19% (in this case, no more than five tons of raw materials are required to produce one ton of starch).

Calculation of the economic efficiency of producing starch from potatoes with a capacity of 25 tons per day showed that with the specified degree of starch content, the payback period for capital costs will be 2.2 years.

Oleg Radin, President of the Association of Russian Manufacturers  starch products "Roskhmalpatoka"

starch products "Roskhmalpatoka"

- It is possible to establish production only if there are large volumes of cheap and high-quality (starch content of at least 19-20%) raw materials. At the same time, the cost of high-quality potatoes should not exceed 6 thousand rubles per ton, otherwise the price of the finished product will be prohibitively high. There are few raw materials with such characteristics in the country.

At the same time, based on the dynamics of potato prices, it can be observed that Russian potatoes are consistently more expensive than European ones. For 2010 - 2014 The average farm price of Russian potatoes is 22% higher than in EU countries.

Andrey Drobyazko, CEO LLC "Mglinsky starch", Bryansk region.

-Our plant produces starch from potato waste. Use ware potatoes for starch, even at a price of 8 rubles. per kg, unprofitable. We purchase raw materials for 1.5 rubles per kg, mainly small or rotten tubers with a starch content of about 10%. Ideally, the starch content should be at least 19%, but no one will specifically plant the varieties we need at such purchasing prices. Our raw material suppliers are potato producers from all over the Bryansk region. Our region is considered a potato region, there are several large producers with large modern storage facilities, and many farmers work. We consistently buy back all the restocks from them, which is convenient for both them and us.

This year we purchased potatoes until May inclusive; we selected every last potato in the region. So, despite the huge harvest, none of the Bryansk producers threw away the potatoes.

Starch producers hope that the state will help them solve the problem with the quality and quantity of raw materials: for example, by paying subsidies to agricultural enterprises growing potato varieties with a high starch content. Experts also see a solution in establishing a close system of interaction between potato producers and processors and in using the accumulated global experience.

Dmitry Lukin

- In Europe, the leaders in the production of potato starch are Sweden, the Netherlands, Germany, and Denmark. In these countries, due to the high labor intensity of growing and storing potato tubers, the following basic principles have been established for stimulating the production of potato starch:

- potato producers (farmers, cooperatives) are shareholders of the processing plant and have a financial interest in the sale of the final product - starch and its derivatives;

- The companies have organized an agronomic service that provides potato producers with recommendations for growing them and seed material for the production of potatoes with a starch content of at least 20%;

- Companies provide loans to potato producers for the purchase of seeds, fertilizers and fuels and lubricants, which is fixed in the contract for the supply of potatoes.

The profitability of starch production is achieved by reducing the cost of growing potatoes with high yields and high starch content - up to 25%. At the same time, the consumption of potatoes per 1 ton of starch is reduced to 4.5 tons and, accordingly, the specific energy costs for its processing are reduced.

Recycling

The issue of waste disposal is also very acute for enterprises involved in potato processing. “Today I will deliver potatoes,” says the director of the plant, which recently produced potato starch, with bitterness, “and tomorrow they will come to me with fines, or even close them down altogether.” Meanwhile, this problem may well have a beneficial solution. In Europe, protein extracted from potato juice is a product of high nutritional value. Fiber, washed and dried, is widely used in the food industry. Is there any experience in recycling waste in Russia?

Dmitry Lukin

- The most common way to dispose of pulp and potato juice is either to use their mixture as animal feed, or to separate this mixture in a centrifuge into two fractions: pulp, used as feed, and potato juice, sent to a storage pond for subsequent fertilizing irrigation agricultural land.

When producing potato starch according to a technological scheme using a hydrocyclone unit, by-products - pulp and potato juice - are obtained in the form of a mixture with a dry matter content of 7-8%, which can be used as a feed product.

One ton of a mixture of pulp and potato juice has 70-80 feed units. For 1000 kg of processed potatoes, about 1050 kg of mixture is produced.

It is recommended to use potato pulp and juice for:

- feeding animals raw;

- preparation of steamed food;

- isolation of proteins from potato juice;

- fertilizing irrigation of farmland (potato juice);

- growing feed yeast or other microorganisms on potato juice or on hydrolysates of the mixture and potato juice;

- receiving dry food.

Potato juice can beused for fertilizing irrigation of agricultural land. Watering with potato juice can reduce the consumption of chemical fertilizers by 15-20%. The juice can also be used to grow yeast or other microorganisms. VNIIK is developing membrane technology for concentrating potato juice in order to obtain a protein concentrate.

Equipment and technologies

There is not much to say about the role these two components play for the success of an enterprise. The lag in this case leads to high transaction costs and, as a consequence, loss of competitiveness in the market.

Leading equipment manufacturers in the world today offer lines with a capacity of 100 to 300 tons per day, which allows the production of up to 5.6 thousand tons of starch per year. The level of starch extraction from raw materials is 98%.

One of the first enterprises in the post-Soviet space to install equipment of this level in its workshops was the Rogoznitsa Starch Plant (occupies key place in the list of the main starch producers in the Republic of Belarus, producing about 40% of the total volume of starch in the country). Now the plant processes about 40,000 tons of raw materials per year and produces up to 5,000 tons of products (according to the magazine “Product.BY” No. 5 (153), March 2015). At the enterprise, manual labor has been reduced to a minimum; the entire technological process - from receiving potatoes to packaging finished products - is managed by one operator.

However, before recommending a very expensive course of modernization to Russian enterprises, it is important to understand how much the product is in demand on the market.

Andrey Drobyazko

- Of course, we could produce starch of the same extra-quality as European starch. To do this, you only need to purchase a Swedish installation for fine purification of starch, that is, invest about 50 million rubles in equipment. In Belarus, at the Rogoznitsa starch plant, they did just that. We can’t afford it yet; the costs won’t pay off.

Does Russia need potato starch?

Back in 2007-2011. about 54% of all starch sales worldwide were from corn starch. The second most important position was occupied by cassava (tapioca) starch (it is produced from root vegetables, but is cheaper than potato starch and does not have a specific odor like corn starch) - about 32%. The share of potato starch remained no more than 7%.

Today, 80% of the starch produced in our country is made from corn. The direction of producing starch from wheat and rye (Russia is a grain power) is also considered promising.

There are fewer and fewer people wishing to produce potato starch; it is too troublesome: the raw material is poorly stored, a lot of it is needed (compare: to produce 1.5 tons of corn starch, only 1.8 tons of corn are required), production itself is seasonal.

Andrey Drobyazko

- In Russia today a little potato starch is produced, but we do not feel a shortage of this product on the market, there is no queue of buyers. Even now, when, due to rising prices for raw materials, corn starch has become more expensive than potato starch, I cannot say that the demand for the latter has increased.

Perhaps you can just forget about potato starch?

- When the potatoes run out, to eliminate the seasonality of the plant’s work, we launch a line for the production of grain starch. Working with grain is much less troublesome, but the country cannot completely abandon potato starch; it has special properties that are important for many industries. It is also necessary to ensure import substitution, since the total volume of imports of native and modified potato starch is quite high - about 40 thousand tons.

Dmitry Lukin

Compared to other types of starch, potato starch has the largest grains - from 15 to 100 microns - and contains the least amount of impurities. Starch consisting of large grains is of higher quality. A significant advantage of potato starch over other types of starches produced from various types starch-containing raw materials is a higher gelling ability, the transparency of its pastes and their increased viscosity and increased reactivity, which is especially important when obtaining various modifications. Unlike grain starches, potato starch contains a reduced amount of protein and does not contain lipids.

Oleg Radin

-Potato starch, in comparison with other types of native starches, has a lower calorie content and a higher content of minerals. The energy value of 100 g of potato starch (in kcal/kJ) is 299/1251 (for comparison, corn starch is 329/1377). It is used mainly for food purposes (92.6%), including as a finished product in retail trade (49.4%), in the production of some types of sausages, frankfurters and sausages (18.2%), in the production fruit and berry jelly (12.3%).

For technical purposes, potato starch is used in the paper industry (3.7%), special production (1.6%), dextrin production (1%), and in the chemical and pharmaceutical industry as a filler in tablet medicines and powders.

PROSPECTS

Does the Russian potato starch industry have a future?

Evgeniy Ivanov, expert at the Institute for Agricultural Market Studies (IKAR), notes that it is too early to put an end to the history of the industry. Just a few years ago it was difficult to imagine that our country would become the largest exporter of wheat. It is quite possible that Russia will achieve success in the production of potato starch, although this will require time, government support and ambitious players in the market. Other experts agree with this opinion.

Dmitry Lukin

For the development of potato starch production, the development of an industry program “Potatoes and their processed products” is required, the need for which is determined by the need to resolve the issue of import substitution of potato native and modified starches, the interests of rural producers in the sale of potatoes and the important role of potato crops in crop rotation.

Given the current state of potato starch production, solving the problem of import substitution of potato starch and its modifications may require at least five years.

A strong argument can be made in favor of the prospects of processing potatoes into starch: in EU countries, in the structure of raw materials, the volume of potato processing is comparable to the volume of processing corn and wheat - 30-35%, while in Russia the share of potato processing is only 5-6%.

Oleg Radin

- The most significant costs (65-75%) in the cost structure of starch products go to raw materials. Based on the fact that up to 75% of funds are borrowed, enterprises attract credit resources for a period of up to 12 months to make purchases. To develop the industry, we need to make it more attractive: short-term loans at a reduced rate, a focus on innovation of domestic technologies brought to industrial use, and resolve the issue of the shortage of qualified personnel.

However, the enterprises themselves can do a lot. Even those who have never previously been involved in the production of starch: for example, agricultural holdings looking for a solution to the issue of misgrading; factories for the production of chips and potato flakes.

According to ICAR expert Evgeniy Ivanov, in the current situation it will be easier for these enterprises to achieve a stable position in the starch market, since they have a wide specialization and are not concentrated on the production of one or two types of goods.

Dmitry Lukin

- In logistics centers involved in the preparation of potatoes for sale in retail chains, when sorting and cleaning tubers, up to 15-20% of substandard products (damaged, small tubers) are formed.

For an enterprise supplying stores with up to 50 thousand tons of potatoes per year, the volume of substandard product can be up to 5-7 thousand tons, from which up to 1000 tons of starch can be obtained using a line for processing potatoes into starch with a capacity of 25-50 tons/ day.

Substandard potatoes are also formed at factories that process potatoes (from 10 to 30 thousand tons per year) into dry mashed potatoes, chips, and French fries. When calibrating and inspecting tubers, mechanical cleaning and cutting, potato waste in such factories reaches 30%.

To process potato waste into starch, based on volumes from 3 to 10 thousand tons per year, the above-mentioned low-tonnage lines for processing potatoes into starch can be installed at each plant.

It should be noted that the interest of agricultural producers in processing potatoes into starch is increasing every year.

Dmitry Lukin

-A particularly significant flow of requests for equipment at the Research Institute of Starch Products was observed this year, which was caused by the high potato yield in 2015. Only in the last 1.5 months, applications for the production of potato starch lines from the Novgorod, Bryansk, and Kemerovo regions have been sent to our Institute.

If we talk about large specialized enterprises, then their development (as well as the industry’s recovery from the crisis) can only be associated with the establishment of the production of modified (i.e., subjected to physical, chemical or biochemical processing to acquire special properties) starches, the need for which is in Russia constantly growing.

Andrey Drobyazko

-To make money from the production of potato starch, you need to produce modified starch. Russia purchases about 80 thousand tons of modified starch annually, with average cost not 32 rub. for 1 kg as for native, and for 90 rubles. But to open such a production, domestic technologies and equipment are needed, while foreign ones are very expensive.

Oleg Radin

- Among the main suppliers are the Republic of Belarus and the countries of the European Union. The largest producers in the EU are:

- AVEBE Potato Producers Cooperative, founded in 1919 (Netherlands, http://www.avebe.com/), is the world leader in the production of potato starch, with sales of 560 million and net profit of 11.8 million in 2014.

- Cooperative of potato producers KMC KARTOFFEL MELCENTRALEN, founded in 1933 (Denmark, http://www. kmc.dk/), with sales volume of 127 million and net profit of 18.8 million for 2014.

- Private company EMSLAND GROUP, founded in 1928 (Germany, http://www.emsland-group.de/), the largest manufacturer of potato starch in Germany with a sales volume of 520 million in 2014.

Unfortunately, at the moment, not a single Russian enterprise producing potato starch can compare with the above companies.

Dmitry Lukin

- Currently, about 25 thousand tons of modified starches are produced in Russia at six factories - mainly from corn starch, which has a lower cost compared to potato starch. The production of 10 types of modified potato starch (oxidized, phosphate, acetate, cationic, cleaved, soluble, adipate, swelling, extrusion) was first mastered and produced for a long time at the Klimovsky starch plant, but in the 90s this production was suspended due to bankruptcy of the plant.

To produce competitive products, it is necessary to develop high-tech technologies for new types of starch modifications, which scientists at the All-Russian Research Institute of Starch Products are currently working on, but the strength of starch producers alone is not enough.

The fact is that modifying starch requires a number of chemical reagents that are not produced in Russia, as well as the use of specialized varieties of potatoes with a high content of amylopectin or amylose, which are not produced in Russia. Therefore, it requires the involvement of potato breeders, scientists chemical industry and consumer industries. This circumstance also requires reflection when developing the above sectoral program for the development of potato processing production.

Experts call modified starch a strategic product, therefore the development of the production of various types of starch modifications, this polymer created by nature itself, amazing in its diversity of properties, should be given special attention to scientists and specialists in both the starch and related industries.

The future of domestic potato and starch production largely depends on the successful implementation of this task.

The production of starch has always remained one of the most promising areas of activity, since this product has not only nutritional value, but also finds application in many industrial sectors. Having equipped a mini-factory and decided on a sales market, you can quickly recoup the investment.

Manufacturing Process Characteristics

Characterizing the technological process, it should be noted that regardless of the raw material from which starch is produced - corn, wheat or traditional potatoes, the basic operations are identical:

- preparation of raw materials - cleaning from foreign impurities, washing, weighing;

- grinding to bring the raw material into a mushy state;

- liquid fraction separation;

- obtaining starch in free form;

- refining – cleaning from pulp particles;

- washing;

- drying;

- packaging;

- package.

The potato crushing operation usually takes place in two stages. The first of them uses files with a tooth height of 1.5 mm. The second stage - grinding involves the use of smaller files with teeth of 1.0 mm.

In order for the starch business to function year-round, it is advisable to purchase a plant for producing molasses according to the following algorithm:

- starch hydrolysis;

- filtering the resulting solution;

- bleaching;

- evaporation of syrup to obtain molasses with standard consistency;

- spilling molasses.

The seasonality of starch production, especially from potatoes, is due to the fact that it can be stored without significant loss of quality for no longer than seven months.

Features, differences from scale lines

One of the motivations for installing a mini-plant focused on starch production is the demand for this type of product. There are a number of other advantages that distinguish small production from large-scale lines.

A small starch plant is attractive for budding entrepreneurs due to its mobility. If necessary, such production can be installed in close proximity to the place where the required raw materials grow, which significantly reduces transportation costs.

Starch plant

Necessary material, equipment

To install a full-fledged starch plant, which is classified as a mini-enterprise, an area of about 75 square meters is sufficient. meters to equip a production workshop and storage facilities. Particular attention should be paid to the arrangement of storage areas for raw materials necessary for processing.

If it is not possible to equip them near production, it is advisable to conclude agreements with farms, who have their own warehouse space, for timely supply of raw materials to ensure smooth operation of the equipment.

A modern technological installation with maximum automation makes it possible to produce four grades of starch, which significantly expands the consumption sector. The main equipment of the mini-plant includes the following machines and mechanisms:

- washing;

- automatic scales;

- industrial grater;

- collection of gruel;

- centrifuge;

- vacuum drying;

- Packaging equipment.

Special attention is paid to the presence of washing machines equipped with sand, tops and stone traps if potatoes are processed. It goes through several stages of washing for almost 15 minutes in order to completely clean its surface from any type of contamination. After washing, the tubers are weighed using automatic scales equipped with a hinged bottom. The weight of incoming batches is recorded by a counter.

Starch after centrifuge in accordance with OST 18-158 standards can contain moisture from 38 to 40% (grade A) or from 50 to 52% (grade B). It is also divided into varieties depending on quality. This product, the so-called raw starch, cannot be stored for long periods of time, so it must go through a drying stage.

Since starch different varieties can be obtained not only from potatoes, but also from corn and wheat, it is advisable to consider the option of integrated use of equipment by organizing the supply of several types of raw materials.

Business plan

Considering that on initial stage In order to establish a business, it is easier to turn to the production of starch from the usual potatoes; it is advisable to establish strong relationships with suppliers of this type of raw material. The main attention is paid to the quality of the tubers, which must be healthy, free of damage, and have rough skin. Only such potatoes can not lose their properties during storage.

Subsequently, having established long-term relationships with consumers, it is possible to expand production by turning to the production of products from corn and wheat. When developing a business plan, you must immediately focus on the needs for different types, as well as varieties of starch, which is in demand in the food, paper, textile, and pharmaceutical industries.

When launching a starch plant, you should consider which staff will be able to effectively perform all the necessary operations. Operators, loaders, and storekeepers will be needed. You will also need a technologist, an accountant, an adjuster, and a forwarding driver. There are about twelve people in total.

Cost, payback

When planning to start your own business producing starch, for example from potatoes, you need to be prepared for large initial investments, since a mini-plant equipped with all mechanisms with a productivity of 1 t/hour ∙ 8 hours ∙ 23 days = 184 t/month will cost approximately 6,000 thousand rubles .

Monthly costs will be, thousand rubles:

- rent – 40;

- salary fund – 300;

- sodium sulfate – 5;

- transportation costs – 150;

- water, electricity – 152.

Financial resources for the purchase of raw materials will be required 5 ∙ 5000 ∙ 184 = 4600 thousand rubles. Based on the calculation that for a ton of produced starch it is necessary to spend 5 tons of potatoes at a purchase price of 5 rubles/kg.

The total cost of starch per month will be 5,247 thousand rubles.

Income is determined based on the wholesale average market price for starch in the amount of 36 rubles/kg.

Total income will be:

36 ∙ 184000 = 6624 thousand rubles.

6624 – 5247 = 1377 thousand rubles.

Taking into account taxes, you can count on net profit at 1171 thousand rubles.

Return on capital costs:

6000 / 1171 ≈ 5 months.

In real conditions, the payback period for mini starch production may take a longer period, but overall the business will generate income.

Video: Starch production line