Technology for the production of starch and starch products. Coursework: Technology for the production of potato starch

In addition to canning potatoes, this raw material is the main one for the production of starch. Starch is produced in large specialized enterprises, in small factories and even in small workshops. As a raw material, you can use both regular ware potatoes and small ones, which, as a rule, are rejected by size when dried or frozen. The main requirement is that the potatoes must be ripe, since young unripe tubers the average size There are fewer starch grains; accordingly, the quality of the finished starch from them will be lower, and the amount of losses during production will be higher.

On average, one tuber contains about 18% starch by weight. When starch is extracted, the cell walls of the raw material are destroyed, and the maximum amount is extracted from them. a large number of starch grains, which are then separated from liquid and impurities and dried. When producing starch, cold water is used, and it is dried at a low temperature. Since dry anhydrous starch has specific gravity 1.65 g per ml, then starch grains, when separated from the pulp cells, quickly precipitate. This allows them to be captured in the form of sediment and separated from the liquid part using a centrifuge.

Starch production consists of several operations. First, all potatoes are washed in a special washing machine, which is equipped with a deep trough with a shaft at the top. Water consumption when washing potatoes is 4-5 cubic meters. meters of water per 1 ton of raw materials. Then, as when canning potatoes, the tubers are crushed. But this time they are crushed in such a way as to destroy maximum amount cell walls (this will allow you to extract as much starch from them as possible). However, excessive grinding will make it difficult to separate them from the starch and liquid later. Therefore, to grind potatoes, they are passed through grating devices, which turn the tubers into a porridge-like mass, the main part of the starch grains in which is in a free state. The mashed potato mass is collected in a collection and then placed on a sieve. The line can use semi-cylindrical, cylindrical (rotary) and flat (shaking) equipment. It is here that, under the influence of water, starch grains are separated from other components of the mass. More than half of the starch passes through the sieve along with water and other substances. In this case, pulp, fiber and about 25% starch remain on the sieve. To reduce losses, the remaining porridge is ground again and passed through a sieve with finer holes. Starch grains that have passed through a sieve along with water are called starch milk. The solution is poured into a separate tank, where the starch is separated from the water by settling in vats, settling in a stream (on trays or in grooves) or by centrifugation. In the first case, the milk is poured into tanks and left for 7-8 hours. The starch settles at the bottom of the tank, and the liquid with the resulting foam is carefully drained through filters to capture the remaining starch. The starch is discharged into a washing vat, where it is again mixed with water and left to settle. The plaque formed during secondary washing is removed from the surface of the water, and the raw starch is sent for drying. Raw material contains up to 55% water. During the drying process at a temperature of 45-50°, its moisture level is reduced to 20%. Since this operation results in the formation of lumps in the starch, they must then be crushed. Finally, the finished starch is sifted through burat and packaged.

Most modern enterprises use automated lines for the production of starch of four grades (extra, highest, first, second). They allow you to perform all operations - washing raw materials, grinding, collecting and cleaning porridge, mechanical dehydration of the resulting starch, separating free starch from porridge, dehydration and drying - with minimal human intervention and using waste-free technology. A special hydrocyclone unit is used to separate potato porridge into a starch suspension and a mixture of pulp and potato juice.

This allows you to significantly reduce the consumption of fresh water, which amounts to in this case about 0.5 cu. meters per 1 ton of potatoes. In addition, wastewater is almost completely eliminated, and the resulting concentrated waste (containing about 7-10% dry matter) is used as livestock feed in natural or processed form. Such installations do not require a large production area for placement and are characterized by high productivity (up to 10-15 tons of starch per day). The cost of such a set of equipment starts from 7 million rubles. When choosing premises for production and warehouses, keep in mind that fine starch dust in the air can explode upon contact with fire. Therefore, at such an enterprise, special requirements are imposed on the equipment of premises where starch is produced (especially in areas where it is dried and packaged), including compliance with fire safety rules. In addition, you will need your own wastewater treatment system or the ability to locate filtration fields near the production site. Such an enterprise should be located outside the city. You also need your own transport: potatoes are delivered to the plant from farms within a 100 km radius. The cost of delivery alone is about 1000 rubles for 6 tons of processed potatoes or 1 ton of finished starch. To service an average production facility, 14-16 people will be required, working in two shifts. The average salary of an employee will be about 18 thousand rubles. Thus, the costs of wages in the cost of 1 ton finished products are 320 rubles. Add to this the costs of purchasing raw materials (potatoes), sodium sulfate, costs of water, electricity, gas, and purchasing packaging (bags). With such figures, the cost of production of 1 ton potato starch is approximately 31-32 thousand rubles.

The average market wholesale price of potato starch is about 37 rubles per kilogram. Thus, the income of an enterprise for the production of potato starch without taking into account tax deductions, as well as the organization of product sales and other costs, in addition to those taken into account above, can amount to 3.5-4 million rubles per month with a productivity of 1-1.5 tons starch per hour. Of course, minus all expenses net profit will be an order of magnitude lower. However, it is possible to increase the profitability of the enterprise by expanding the range, selling waste from potato processing (fiber) as feed, etc.

The potato canning and starch production business is seasonal. Since during storage potatoes lose most starch contained in it, the raw material processing season is about 250-300 days - from September to May. But to obtain starch more High Quality It is recommended to process all potatoes within 200 days. Already from April (and in some regions even earlier), starch losses increase significantly.

Sysoeva Lilia

- portal of business plans and manuals

Potato starch. Potato starch production, technology

The main task of potato starch production is maximum extraction of starch by breaking the largest number of tuber cells and further purification of starch grains from insoluble and soluble impurities. The entire process of such production consists mainly of mechanical operations and is based on two properties of starch grains: their insolubility in cold water and their small size with a relatively high density.

Let's consider a scheme for obtaining raw potato starch.

Potato tubers are washed well from the soil in special sinks, separating straw, stones and other contaminants. Clean tubers are crushed using graters or impact chopping machines. The resulting porridge is processed in precipitation centrifuges to obtain concentrated cell juice. The porridge after centrifuges is diluted with liquid starch milk from the sieves on which the fine pulp was washed, and sent to the first two sieves, which successively wash the starch from the pulp.

From the sieves, the porridge is sent for final abrasion to a second grinding machine, washed from free starch, and the resulting pulp is sent for mechanical dehydration and use as feed. The last washing sieve for pulp receives return production water after washing the starch.

The starch milk obtained after washing the porridge is supplied to separate juice water into auger (precipitation) centrifuges. Juice water is removed into traps, and raw starch, diluted with fresh water, in the form of milk is sent for refining in special sieve apparatus with a thin nylon mesh that separates small particles of pulp. The fine pulp is usually washed separately on sieves with a nylon mesh, and the resulting liquid starch milk is sent to dilute the porridge after the second isolation of cell juice. The pulp is used in the production of feed.

Refined starch milk still contains small amounts of residual soluble substances and tiny particles of pulp. Therefore, it is sent to the final cleaning operation - washing in continuously operating hydrocyclone stations. Here, pure raw starch and some starch of reduced quality are obtained. The latter is processed separately to produce low-grade starch or, after careful additional purification, is returned to the main circuit before refining starch milk.

The quality of raw potato starch must meet the requirements of the industry standard OST-18-158-74. In accordance with this standard, two grades of raw starch are distinguished according to their moisture content: A (38-40%) and B (50-52%). In addition, according to the quality of each brand of starch, they are divided into three grades - I, II and III. Starch of grades I and II must have a homogeneous White color and the smell characteristic of starch (foreign odor is not allowed). Grade III starch may be grayish, without streaks or inclusions. It has a slightly sour, but not musty smell.

Due to high humidity (38-52%), raw potato starch is a semi-finished product, and it is processed to produce such types of finished products as dry starch, acid-free dextrins, modified starches, starch sago, various molasses, glucose.

To obtain high-quality finished products, good quality of raw materials (raw potatoes) is very important, and sometimes even decisive. The white color of starch is important when used as an auxiliary material in textile, paper, printing, food and other industries. Of great importance for many industries is the viscosity of the starch paste obtained by heating a mixture of starch and water. A feature of potato starch that distinguishes it from many other starches is the high initial viscosity of the starch paste. However, if the technological process is carried out incorrectly, the viscosity of such a paste can greatly decrease. The main influence on this is the long stay of starch grains in water containing a significant concentration of cell sap, the presence of dissolved calcium and magnesium salts (water hardness) and some other factors. Raw starch does not store well due to its high moisture content. Therefore, immediately after production, it is advisable to dehydrate it (in centrifuges), and then either immediately dry it or process it to obtain other types of finished products.

The yield of starch depends most on the starchiness of the potato and the quality of its grinding. Since potatoes lose a significant amount of starch during storage, they are processed as quickly as possible, avoiding storage in the spring months. Therefore, the usual potato processing season lasts 180-200 days - from September to March. In the spring and summer months, potatoes are processed with significantly worse performance. Aim should be made to extend the processing season to 120 days.

Corn starch. Corn starch production technology

The goal of the raw corn starch production process is to maximize the extraction of this polysaccharide from the grain in the purest form possible and with minimal change in its natural properties, effectively separating it and preparing it for processing other valuable components grain, germ, shells, protein substances and soluble compounds.

This goal is achieved in production by using the following methods of influencing grain and intermediate products obtained during its processing:

chemical, physical and biological in order to soften the grain during the soaking process to facilitate its subsequent separation into components;

multi-stage wet grinding of grain with preservation of the whole embryo, minimal destruction of the grain shells and maximum release of starch grains from the cells;

isolating and washing the embryo and membranes using wet sieve;

separation of protein particles and starch grains of different density and size under the influence of centrifugal forces using high-speed centrifugal separators.

Various microbiological processes occur in the production of corn starch. In one case, when soaking grain, directed lactic acid fermentation not only does not interfere, but also helps production, but in others, for example, when grinding grain, sieving and separating starch and protein, the development of microflora complicates work and worsens the quality of the finished product.

The production of corn starch includes the following main technological operations (diagram):

soaking grain in a warm solution of dilute sulfurous acid in order to soften the grain and remove most of the soluble substances from it;

crushing soaked grain to isolate the germ;

isolation and washing of the embryo;

fine wet grinding of grain porridge to release bound starch grains enclosed in endosperm cells;

separation of particles of grain shells and endosperm cell walls from the starch suspension, separation of free starch from them by washing and wet sieve;

separation of starch-protein suspension in order to isolate suspended protein substances;

washing starch to clean it from the remainder of dissolved mainly nitrogenous substances.

http://carbofood.ru/starch-technology/

Due to the diversity of its properties and the ability to change them, starch is used in different food production(confectionery, bakery, sausage, etc.), in cooking, for the production of starch products, in non-food industries (perfume, textile, etc.).

Calorie content of 100g of starch is 350 kcal. In plant cells, starch is found in the form of dense structures called starch grains. Starch grains of different plants are characterized by a certain shape, structure, and size. Based on these characteristics, the type of starch can be determined. Starch can be made using various plant materials. However, the production technology is slightly different. In this article we will describe the technology for producing starch from potatoes and corn.

Potato starch production

The potatoes are washed to remove dirt and foreign inclusions in a potato washer, then served for chopping. The more it is crushed, the more complete the release of starch from the cells will be, but it is important not to damage the starch grains themselves. First, the potatoes are crushed twice on high-speed potato graters. The principle of their operation is to abrade the tubers between the working surfaces formed by saws with fine teeth mounted on a rotating drum. On the first grinding graters, the files protrude above the surface of the drum by 1.5...1.7 mm, on the second grinding graters - no more than 1 mm. During the second grinding, an additional 3...5% of starch is extracted. The quality of chopping also depends on the condition of the potatoes (fresh potatoes shred better than frozen or limp ones).

After crushing the tubers, ensuring the opening of most of the cells, a mixture is obtained consisting of starch, almost completely destroyed cell membranes, a certain amount of undestroyed cells and potato juice. This mixture is called potato porridge. Starch remaining in unbroken cells is lost as a by-product of production - potato pulp. This starch is usually called bound, and that isolated from potato tubers is called free. The degree of potato grinding is assessed, which characterizes the completeness of cell destruction and the amount of starch extraction. It is determined by the ratio of free starch in the porridge to the total starch content in potatoes. During normal operation it should not be less than 90%. To improve the quality of starch, its whiteness and prevent the development of microorganisms, sulfur dioxide or sulfurous acid is added to potato porridge.

The nitrogenous substances in juice include tyrosine, which is oxidized under the action of the enzyme tyrosinase to form colored compounds that can be sorbed by starch grains and reduce the whiteness of the finished product. Therefore, the juice is separated from the porridge immediately after grinding. Hydrocyclones are used to separate sand from the starch suspension and separate the pulp from potato juice. The principle of their operation is based on the centrifugal force generated during rotation. As a result of processing, a starch suspension with a concentration of 37...40% is obtained. They call her raw potato starch.

To dry starch, continuously operating pneumatic dryers of various designs are most often used. Their work is based on the principle of drying loosened starch in a moving stream of hot air. The yield of finished starch depends on its content in the processed potatoes and on the loss of starch with by-products and wastewater. In this regard, the starch content in potatoes supplied for processing is standardized by the standard and should be at least 13...15%, depending on the cultivation zone.

When producing starch, it is produced in two forms: dry and raw potato starch. The amount of raw potato starch is determined in accordance with OST 10-103-88. There are raw starch grade A and grade B with a moisture content of 38 and 50%, respectively. Depending on the quality (color, presence of inclusions, foreign odor), raw starch is divided into three grades - first, second and third. Raw starch is a perishable product and cannot be stored for long periods; 0.05% concentration of sulfur dioxide can be used for preservation.

Dry starch is packaged in bags and small packages. Potato starch is packaged in double fabric or paper bags, as well as bags with polyethylene liners weighing no more than 50 kg. In terms of quality, starch, in accordance with the requirements of GOST 7699-78 “Potato starch” is divided into the following grades: “Extra”, highest, first and second. Starch moisture content should be 17...20%, ash content 0.3...1.0%, acidity 6...20° depending on the variety. The content of sulfur dioxide is not more than 0.005%. An important indicator characterizing the purity and whiteness of starch is the number of specks per 1 square dm when viewed with the naked eye. For “Extra” - 80, for the highest - 280, for the first - 700, for the second it is not standardized. Second grade starch is intended only for technical purposes and industrial processing. The guaranteed shelf life of starch is 2 years from the date of production at a relative air humidity of no more than 75%.

Corn starch production

IN general outline, the corn processing process can be described as follows: the shelled corn is softened in hot water containing sulfur. With coarse grinding, the germ is separated, and with fine grinding, fiber and starch are separated. The mill effluent is cleared of gluten and washed repeatedly in hydrocyclones to remove the last traces of protein and obtain high-quality starch.

CLEANING.The raw material for wet grinding is threshed corn. The grain is inspected and cobs, straw, dust and foreign materials are removed. Typically cleaning is done twice before grinding. After the second cleaning, the corn is divided into portions by weight and placed in bins. From the bunkers it is hydraulically fed into the locking vats.

SOAK.Proper soaking is a necessary condition high output and good quality starch. Soaking is carried out in a continuous counter-current process. The shelled corn is loaded into a battery of large locking containers (tanks), where it swells in hot water for about fifty hours. In fact, steeping is a controlled fermentation, and adding 1000-2000 ppm of sulfur dioxide to the steeping water helps control this fermentation. Soaking in the presence of sulfur dioxide directs fermentation by accelerating the growth of beneficial microorganisms, preferably lactobacilli, while inhibiting harmful bacteria, molds, fungi and yeasts. The soluble substances are extracted and the grains are softened. The grains more than double in volume and their moisture content increases from approximately 15% to 45%.

Scheme of grain soaking at a plant with a capacity of 150 tons of corn per day

EVAPORATION OF SOAP WATER. The steep water is drained from the grain and condensed in a multi-stage evaporation plant. Majority organic acids, formed during fermentation, are volatile and evaporate along with water. Consequently, condensate from the first stage of the evaporation plant must be neutralized after heat recovery by heating the water supplied for soaking. The depleted steep water, containing 6-7% dry matter, is continuously withdrawn for subsequent concentration. The steep water is condensed into a self-sterile product - a nutrient for the microbiological industry, or concentrated to approximately 48% solids and mixed and dried with fiber.

SO2 PRODUCTION.Sulfurous acid is used to soak and soften the corn grain and control microbiological activity during the process. Sulfur dioxide is produced by burning sulfur and absorbing the resulting gas with water. Absorption occurs in absorption columns where the gas is sprayed with water. Sulfurous acid collected in intermediate containers. Sulfur dioxide can also be stored in pressurized steel cylinders.

SEPARATION OF THE EMBER . The softened grains are destroyed in abrasive mills to remove the shell and destroy the bonds between the germ and the endosperm. Water is added to support the wet grinding process. Good soaking ensures free separation of the intact germ from the grains during the soft grinding process without releasing oil. Oil constitutes half the weight of the embryo at this stage, and the embryo is easily separated by centrifugal force. Light embryos are separated from the main suspension using hydrocyclones designed to separate the primary embryo. For complete separation, the product stream with the remaining germ is subjected to re-grinding, followed by separation on hydrocyclones, which effectively removes the residual - secondary - germ. The germs are washed repeatedly in countercurrent on a three-stage sieve to remove starch. Clean water is added at the last stage.

Separating the germ at a plant with a capacity of 150 tons of corn per day

Potatoes in the conditions of our country, especially in middle lane, is the main raw material for the production of starch. Starch from potatoes can be produced both in large specialized enterprises and in small factories and workshops at food factories in the local industrial system, on collective and state farms.

The raw material for starch production can be standard ware potatoes, as well as small ones discarded during drying or canning, and sometimes potato waste generated during peeling.

As you know, starch is the most important component of potatoes and is a reserve nutrient necessary for the respiration process of the tuber during storage and for the germination and initial development of a new plant after planting.

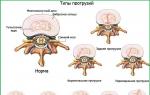

Adjacent to the outer suberized layer (skin) are several layers of flat cells that do not contain starch. The entire interior of the tuber consists of rounded cells containing starch grains. As can be seen in Fig. 86, starch grains are concentrated in the central part of the cells and are surrounded by cell sap, which contains proteins, sugars, and minerals dissolved in water.

Starch grains, even in one cell, have different sizes - from 40 to 80 microns. In general, the average size of starch grains in young immature tubers is smaller than in mature ware potatoes. This is significant, since the larger the starch grains, the better quality finished starch and the less losses in its production. Therefore, normally mature potatoes should be sent for processing.

On average, potatoes contain starch 17-18% of the weight of the tubers, but there are fluctuations from 8-10 to 20%. In the production of starch, the task is to destroy the cell walls, extracting as much as possible from them. possible quantity starch grains, separating these grains from the liquid and from all impurities and drying the wet starch.

To properly build starch production, you should know some of its important properties.

IN cold water starch is insoluble, when hot it turns into a paste. Gelatinization occurs at a temperature of 62-65°, but already at 55° starch grains begin to swell. It follows that when obtaining starch from tubers, you can use cold water, and the resulting starch must be dried at a low temperature.

Dry anhydrous starch has a specific gravity of 1.65 g/ml. This makes it possible to quite quickly precipitate starch grains extracted from the tuber pulp cells, and quite completely capture them in the form of sediment or separate them from the liquid part by centrifugation.

Starch is hygroscopic, it absorbs moisture from the air and, if stored in an unsealed container, its moisture content settles at about 20%. It should be dried to approximately this level.

You need to know that fine starch dust in the air can explode upon contact with fire. Therefore, in the room where starch is obtained, especially where it is dried and packaged, you cannot light matches, place kerosene and other similar lamps, etc.

If a drop of iodine solution is added to a starch solution or paste, the starch immediately becomes intensely Blue colour. Thanks to this, you can easily detect the presence of even traces of starch in various products, in wash waters, etc., which is important for determining and reducing starch losses in production.

Technological process. In a small enterprise, the starch production process is usually structured as follows.

The first operation is washing potatoes. The most convenient for this purpose is a fist washing machine, which is a deep trench with a shaft at the top. Strong wooden blades are attached to the shaft, which, when the shaft rotates, mix the potatoes in a trough with water. To wash 1 ton of potatoes, 4-5 m3 of water is required.

The next important operation is chopping the potatoes. It is necessary to crush the tubers so that the maximum number of cell walls is destroyed, in which case the most complete extraction of starch is ensured. At the same time, the cell walls themselves cannot be overly crushed: very small particles are subsequently more difficult to separate from starch and liquid.

Potatoes are passed through special grating devices or machines. The tubers fall into the space above a rapidly rotating drum, along the side of which a large number of metal files are fixed parallel to the axis. The small teeth of the saws tear the cells, and a semi-liquid crushed mass of “porridge” comes out of the grating device, in which the main part of the starch grains is in a free state.

Grating machines are manufactured in different designs - in relation to different conditions work. It is necessary to ensure constant monitoring of proper work grating machines, promptly change dull files or entire replacement drums, adjust the gaps between files and clamping devices, etc.

The resulting potato porridge is collected in a separate collection. The porridge is fed by a pump to a sieve apparatus, where the starch grains are separated from the remaining components with the help of water. Such devices are manufactured various designs- with semi-cylindrical, cylindrical (rotary devices) and flat (shaking) sieves.

About 75% of starch passes through the sieves along with water and dissolved other potato substances (water consumption 5-5.5 m3 per 1 g of processed potatoes). The sieves retain fiber and pulp, in which a certain amount of starch remains. To separate this starch, the porridge is ground a second time and passed through an apparatus with smaller sieve openings.

The starch grains that have passed through the sieves along with water - the so-called starch milk - are poured into a collection. Starch is isolated from it using one of the methods accepted in industry: by settling in a calm state in vats; settling in a stream - in gutters or on trays; centrifugation.

When working using the settling method, the milk is poured into tanks about 15 m high and left for 7-8 hours. Starch settles at the bottom and accumulates above the liquid layer white light and stable foam.

This foam is removed, then the liquid (called "juice water") is drained, passing it through special traps to retain and trap starch, which is sometimes entrained in the liquid flow. The dense layer of starch remaining at the bottom is unloaded from the settling tank into another vessel - a washing tank, where it is thoroughly mixed with water again and allowed to settle.

Since even after washing twice it is not possible to completely remove all suspended and other impurities, usually on top, above the starch layer, a small grayish coating forms in the vat. This plaque can be removed manually or using special device, and pure raw starch is unloaded from the vat and sent for drying.

At larger enterprises, such starch is slightly diluted with water and transported to the drying department by pumps in the form of thick milk. The removed top dirty layer contains a lot of starch and is processed separately in order to capture and use this starch.

The resulting raw starch contains about 50-55% water. To avoid possible damage (souring) during long-term storage, it should be dried. Starch is dried in drum, tunnel and other types of dryers. The temperature of the product during drying should not rise above 50-55°; It is advisable to maintain it at 45°.

Dry starch comes out of the dryer with a moisture content of 20%. Since the product usually clumps during the drying process, it is first crushed, then sifted and packed into bags.

In modern industry, more advanced machines and entire units have been created to obtain ready-made food starch from potatoes. The most convenient and therefore widely used are potato processing units APCh-25, PKA-10, AP-10 and AKPCH-25 with a capacity of 25 and 10 g of processed potatoes per day.

All main processes for processing raw materials and semi-finished products are carried out on the same unit, which significantly simplifies and reduces the cost of production. The units can be used to organize continuous potato processing with maximum use and low losses of raw materials.

The potatoes are transported into the washing machine using an inclined auger. While still in the auger, the potatoes are irrigated with jets of water and partially washed off dirt. In the washing machine, the tubers pass sequentially through two wet and one dry chambers, where heavy and light impurities are separated and the tubers are finally washed.

Clean water enters through the water distribution manifold on the unit itself; dirty water discharged into the sewer. Clean potatoes are thrown into the chute by the blades of the potato washer, and from there onto the grating device. From here, the resulting potato porridge is collected in a gutter (collector) below, where it is liquefied with twice the amount of settling (“juice”) water coming from a settling-filtering centrifuge. With the help of a four-plunger pump, this porridge enters the drum of a two-product precipitation centrifuge; here it is partially separated from the cell sap and enters a collection above a centrifuge.

In the collection, the porridge is diluted clean water to a density of about 5° according to Br. and pumped with the third plunger onto the first sieve (rotary) to separate the juice. The juice is collected in a settling tank-trap. On the first sieve, the starch is not completely washed out of the porridge. The “half-porridge” coming off this sieve is fed to a brush sieve, and the starch milk that has passed through the first sieve flows by gravity into the second drum of the centrifuge, where juice water is released from it.

Using a brush sieve, the starch remaining in it is washed out of the half-porridge, which is combined with the bulk of the starch obtained on the first sieve. All starch in the form of milk with a density of 3-5° according to Br. then it is fed to the second drum of a two-product centrifuge, where the starch milk is brought to 40° Br. The pulp coming off the brush sieve is dumped into a collection box and, after being slightly diluted with water, it is removed from the unit into a pit for collecting pulp.

In a collection under a centrifuge, the condensed starch milk is diluted with clean water again to 3-5° Br. and the second plunger of the pump is pumped to the rotary sieve of the first cleaning (refining), from where it is pumped to the second sieve.

On this sieve, the starch is washed from the fine pulp and fed by gravity to a settling-filtering centrifuge, where it is dehydrated in a thin layer with continuous movement to a moisture content of 38-40%. This “jointed” starch is then sent for drying. The dryer is not included in the APCh-25 and PKA-10 units. We recommend a drum dryer KS-50 with a capacity of 1 ton of starch per day, a pneumatic dryer (4 tons/day) or a combined dryer (4 tons/day).

In the AKPCH-25 potato processing unit, the dryer is an integral part of the overall circuit.

All potato processing units are distinguished by their compactness, small required area, ease of maintenance, high efficiency in terms of completeness of starch extraction and specific consumption of water, electricity, etc. Therefore, they can be recommended for implementation.

Due to the diversity of its properties and the ability to change them, starch is used in various food industries (confectionery, bakery, sausage, etc.), in cooking, for the production of starch products, in non-food industries (perfume, textiles, etc.).

Calorie content of 100g of starch is 350 kcal. In plant cells, starch is found in the form of dense structures called starch grains. Starch grains of different plants are characterized by a certain shape, structure, and size. Based on these characteristics, the type of starch can be determined. Starch can be made using various plant materials. However, the production technology is slightly different. In this article we will describe the technology for producing starch from potatoes and corn.

Potato starch production

The potatoes are washed to remove dirt and foreign inclusions in a potato washer, then served for chopping. The more it is crushed, the more complete the release of starch from the cells will be, but it is important not to damage the starch grains themselves. First, the potatoes are crushed twice on high-speed potato graters. The principle of their operation is to abrade the tubers between the working surfaces formed by saws with fine teeth mounted on a rotating drum. On the first grinding graters, the files protrude above the surface of the drum by 1.5...1.7 mm, on the second grinding graters - no more than 1 mm. During the second grinding, an additional 3...5% of starch is extracted. The quality of chopping also depends on the condition of the potatoes (fresh potatoes shred better than frozen or limp ones).

After crushing the tubers, ensuring the opening of most of the cells, a mixture is obtained consisting of starch, almost completely destroyed cell membranes, a certain amount of undestroyed cells and potato juice. This mixture is called potato porridge. Starch remaining in unbroken cells is lost as a by-product of production - potato pulp. This starch is usually called bound, and that isolated from potato tubers is called free. The degree of potato grinding is assessed, which characterizes the completeness of cell destruction and the amount of starch extraction. It is determined by the ratio of free starch in the porridge to the total starch content in potatoes. During normal operation it should not be less than 90%. To improve the quality of starch, its whiteness and prevent the development of microorganisms, sulfur dioxide or sulfurous acid is added to potato porridge.

The nitrogenous substances in juice include tyrosine, which is oxidized under the action of the enzyme tyrosinase to form colored compounds that can be sorbed by starch grains and reduce the whiteness of the finished product. Therefore, the juice is separated from the porridge immediately after grinding. Hydrocyclones are used to separate sand from the starch suspension and separate the pulp from potato juice. The principle of their operation is based on the centrifugal force generated during rotation. As a result of processing, a starch suspension with a concentration of 37...40% is obtained. They call her raw potato starch.

To dry starch, continuously operating pneumatic dryers of various designs are most often used. Their work is based on the principle of drying loosened starch in a moving stream of hot air. The yield of finished starch depends on its content in the processed potatoes and on the loss of starch with by-products and wastewater. In this regard, the starch content in potatoes supplied for processing is standardized by the standard and should be at least 13...15%, depending on the cultivation zone.

When producing starch, it is produced in two forms: dry and raw potato starch. The amount of raw potato starch is determined in accordance with OST 10-103-88. There are raw starch grade A and grade B with a moisture content of 38 and 50%, respectively. Depending on the quality (color, presence of inclusions, foreign odor), raw starch is divided into three grades - first, second and third. Raw starch is a perishable product and cannot be stored for long periods; 0.05% concentration of sulfur dioxide can be used for preservation.

Dry starch is packaged in bags and small packages. Potato starch is packaged in double fabric or paper bags, as well as bags with polyethylene liners weighing no more than 50 kg. In terms of quality, starch, in accordance with the requirements of GOST 7699-78 “Potato starch” is divided into the following grades: “Extra”, highest, first and second. Starch moisture content should be 17...20%, ash content 0.3...1.0%, acidity 6...20° depending on the variety. The content of sulfur dioxide is not more than 0.005%. An important indicator characterizing the purity and whiteness of starch is the number of specks per 1 square dm when viewed with the naked eye. For “Extra” - 80, for the highest - 280, for the first - 700, for the second it is not standardized. Second grade starch is intended only for technical purposes and industrial processing. The guaranteed shelf life of starch is 2 years from the date of production at a relative air humidity of no more than 75%.

Corn starch production

In general terms, the corn processing process can be described as follows: shelled corn is softened in hot water containing sulfur. With coarse grinding, the germ is separated, and with fine grinding, fiber and starch are separated. The mill effluent is cleared of gluten and washed repeatedly in hydrocyclones to remove the last traces of protein and obtain high-quality starch.

CLEANING.The raw material for wet grinding is threshed corn. The grain is inspected and cobs, straw, dust and foreign materials are removed. Typically cleaning is done twice before grinding. After the second cleaning, the corn is divided into portions by weight and placed in bins. From the bunkers it is hydraulically fed into the locking vats.

SOAK.Proper soaking is a prerequisite for high yield and good quality starch. Soaking is carried out in a continuous counter-current process. The shelled corn is loaded into a battery of large locking containers (tanks), where it swells in hot water for about fifty hours. In fact, steeping is a controlled fermentation, and adding 1000-2000 ppm of sulfur dioxide to the steeping water helps control this fermentation. Soaking in the presence of sulfur dioxide directs fermentation by accelerating the growth of beneficial microorganisms, preferably lactobacilli, while inhibiting harmful bacteria, molds, fungi and yeasts. The soluble substances are extracted and the grains are softened. The grains more than double in volume and their moisture content increases from approximately 15% to 45%.

Scheme of grain soaking at a plant with a capacity of 150 tons of corn per day

EVAPORATION OF SOAP WATER. The steep water is drained from the grain and condensed in a multi-stage evaporation plant. Most organic acids formed during fermentation are volatile and evaporate along with the water. Consequently, condensate from the first stage of the evaporation plant must be neutralized after heat recovery by heating the water supplied for soaking. The depleted steep water, containing 6-7% dry matter, is continuously withdrawn for subsequent concentration. The steep water is condensed into a self-sterile product - a nutrient for the microbiological industry, or concentrated to approximately 48% solids and mixed and dried with fiber.

SO2 PRODUCTION.Sulfurous acid is used to soak and soften the corn grain and control microbiological activity during the process. Sulfur dioxide is produced by burning sulfur and absorbing the resulting gas with water. Absorption occurs in absorption columns where the gas is sprayed with water. Sulfurous acid is collected in intermediate containers. Sulfur dioxide can also be stored in pressurized steel cylinders.

SEPARATION OF THE EMBER . The softened grains are destroyed in abrasive mills to remove the shell and destroy the bonds between the germ and the endosperm. Water is added to support the wet grinding process. Good soaking ensures free separation of the intact germ from the grains during the soft grinding process without releasing oil. Oil constitutes half the weight of the embryo at this stage, and the embryo is easily separated by centrifugal force. Light embryos are separated from the main suspension using hydrocyclones designed to separate the primary embryo. For complete separation, the product stream with the remaining germ is subjected to re-grinding, followed by separation on hydrocyclones, which effectively removes the residual - secondary - germ. The germs are washed repeatedly in countercurrent on a three-stage sieve to remove starch. Clean water is added at the last stage.

Separating the germ at a plant with a capacity of 150 tons of corn per day